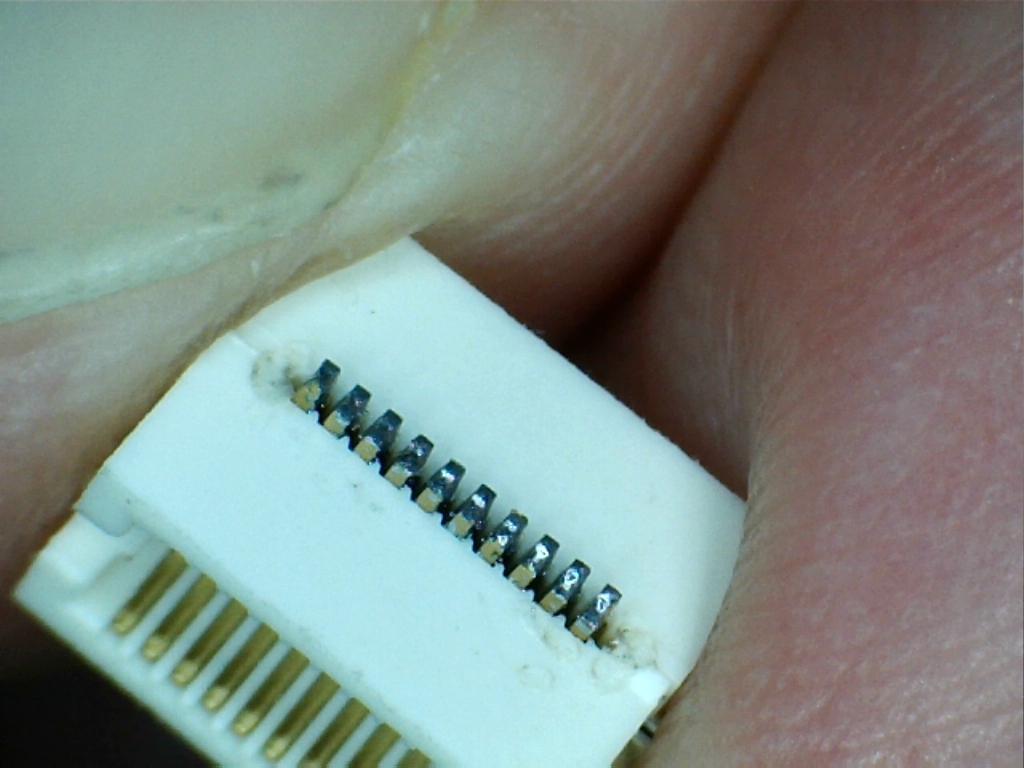

As a circuit designer and systems engineer most of my time is spent in front of a PC screen. There is still a need to test my creations and work around unexpected events though. One of those unexpected events was finding that there had been a misunderstanding over the part number of the connector that mates with the connector being fitted to the control board designed by my customer. To test my boards two male connectors had to mate. The temporary solution is to produce what is often referred to as gender bender. In this case two female connectors soldered back to back. The slight difficulty with this approach is that the connectors are surface mount types with a 0.5mm pitch. With a steady hand, a fine soldering iron tip, and a good stereo microscope I managed it.

Back to back SM connectors

I first tacked the two together with blobs of hot melt glue at either end. Dong this quickly allowed me to make a final adjustment to the alignment of the two connectors before the glue cooled and set. I didn’t have any really fine solder so opted to use solder paste instead. The trick here is not to use too much. I put a smear of paste across the pins them wiped most of it off. I then heated each pair of pins with a soldering iron enough to melt the solder on them but still leave the solder balls in the paste between adjacent pins solid. Finally I cleaned away the unwanted paste with solvent and a short bristled brush. This was quite hard as the brush bristles were as wide as the gaps between adjacent pins.

This goes to show that the old skills are still needed even in this modern world of ultra small surface mount components.