Occasionally I come across individuals who have been in the industry a very long time, and have become great experts in their field, often ending up working as independent consultants. Bruce Carsten is one of them. He even has a grey beard, at least on the probably quite out of date photo on his website. Ancient RF experts were once referred to as “grey beards”, back in the days when it was more wizardry than the modern CAD driven engineering of today. The gems of knowledge that attracted my attention were Bruce’s work on inductor and transformer design. Some excellent papers of his can be found on the Micrometals website. Happy reading.

Category Archives: Uncategorized

RS is 80!

Working in an industry where rapid change is the norm, it comes as a bit of a surprise to learn that RS, one of the dominant 3 broadline distributors has been around for 80 years. The others are Farnell and Digikey.

RS was originally called Radiospares, the company started in 1937 in the UK. They now have operations in 30 countries across Europe, North America and Asia. Although I occasionally use the others, plus Mouser, RS is my preferred choice of component supplier (other than Golledge of course) because their component search engine is a bit more sorted than the other broadlines, their lack of a minimum order value, and free next day delivery. The free delivery must be a loss leader for some small orders. I wish them many more prosperous decades to come.

More details on RS being 80 can be found here.

SamacSys Component Search

This is a great CAD library, search tool, and library part builder. It works with most of the common electronic circuit CAD programmes. The search interface can be found here. I particularly like the quick component builder that lets you create your own library elements and then share them with other users. It has already saved me a great deal of time, as it is much faster creating new library parts for Eagle than using the component editor within Eagle, even when starting from a similar part already in Eagle.

For the uninitiated Eagle is the schematic capture and PCB design tool I use at Gollege.

Ultra Miniture Antenna Using Acoustic Resonators

I have recent ley come across academic papers making big claims in radio antenna miniaturisation. This paper in Nature using SAW resonators and this one in IEEE Transactions on Antennas and Propagation using bulk acoustic wave (BAW) resonators. It may be quite a while before this technology is available as usable devices on the market, but it always good to know what is on the horizon.

10 Must-Have Skills for All Engineers

An excellent read.

10 Must-Have Skills for All Engineers.

The Importance of low phase noise in ADC and DAC clocks

There are a couple of excellent articles on the effects of sample clock phase noise on DAC and ADC performance from Analog Devices.

Analyzing and Managing the Impact of Supply Noise and Clock Jitter on High Speed DAC Phase Noise

Sampled Systems and the Effects of Clock Phase Noise and Jitter.

Also another good paper from TI.

Why phase noise matters in RF sampling converters.

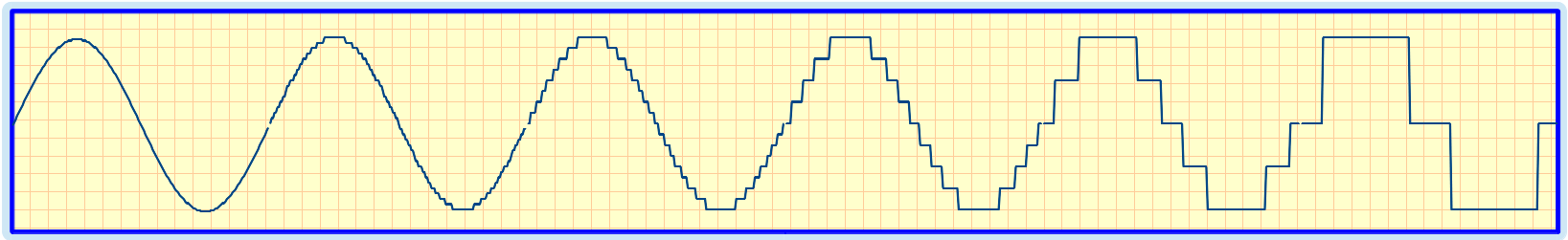

There is a trend in radio system design towards doing ever more of the signal processing in the digital domain. This has been enabled by DAC, ADC, and signal processing blocks, with ever faster sample rates, driven by the process shrinks as predicted by Moore’s Law. These process shrinks have also delivered lower power consumption making this design approach suitable for battery powered products and easing thermal design issues.

In all analogue radio designs, the phase noise of the local oscillator was key to radio performance. While this is still true of mixed analogue/digital designs, arguably the DAC/ADC clock has become just as important. When these clocks were in the 10s of MHz supplying a good quality clock was achieved by buying a good quality crystal oscillator. Now these clocks are in the 100s of MHz and GHz, achieving low phase noise and hence jitter is not so straight forward, as off-the-shelf crystal oscillators are only available up to about 100MHz. Beyond that oscillator modules use PLL based multipliers which inevitably add phase noise. At Golledge I have designed a 290MHz crystal oscillator using one of their high frequency fundamental mode resonators. Much above this, ultra low phase noise sources must look to other high Q resonators, such as SAW resonators. I hope to write more on this later.

Neat new battery technology

Take a look at this new item about a steel – brass battery. The electrolyte is a potassium hydroxide solution.

Unfortunately the fine details are behind a pay wall.

Chaos in Radio

There is an interesting article in EETimes about chaotic oscillator circuits. It made me think of mobile radio groups where all members run AFC. Designers usually avoid using the receive AFC setting to adjust the transmit frequency, unless there is one known good node in the network that others can synchronise with. When all nodes are equal and transmit frequency is based on the last signal seen, then it has been assumed that the group as a whole will wander off frequency and also may split up. This work suggest there may be some cleaver alternatives.

Looking for papers for ARMMS.

I’m technical co-ordinator for the next conference of ARMMS. This involves recruiting presenters of technical papers of interest to RF and Microwave engineers and academic researchers. If you would like to present a paper please let me know.

Refresher on the world of programming

Is Tomorrow’s Embedded-Systems Programming Language Still C?

For those of us who only occasionally write code for a living this is useful update on where the world of programming is going with an emphases on embedded microcontrollers and IoT. Well worth a read.